What if learning new words were as effortless as telling the time?

Who Individual Project

When 2 weeks

Why Graduate Bootcamp Expo

How Woodoworking | CAD Designing | Programming | Soldering

Define

the brief

Define and complete an exploratory project in a two week timespan to present at a graduate school bootcamp Bootcamp Showcase. The work should not be designed for others, but rather show the creator’s 2D visualization and communication, 3D modeling, Solidworks, and mechatronics skills.

Deliberate

on my experience with the topic

The project should help me achieve a pre-existing personal goal: Memorizing all 1065 three-letter Scrabble words.

I’m not usually motivated by designing for myself — only for others

I’m unfamiliar with the NU Machine Shop

I need to express my personality to my new cohortmates

I should showcase my background in 3D modeling, Solidworks, mechatronics, presentation skills

what exists in the landscape

Discover

Habit formation by reading Atomic Habits

New vocabulary acquisition

Features that personally keep me motivated to push myself hard, both as a user and a designer

Define (part 2)

the new brief

Develop

product features

Form sketching | Table-Sawing | Laser Cutting | CAD Designing | Arduino Programming | Soldering

Form Study

Process planning sketches

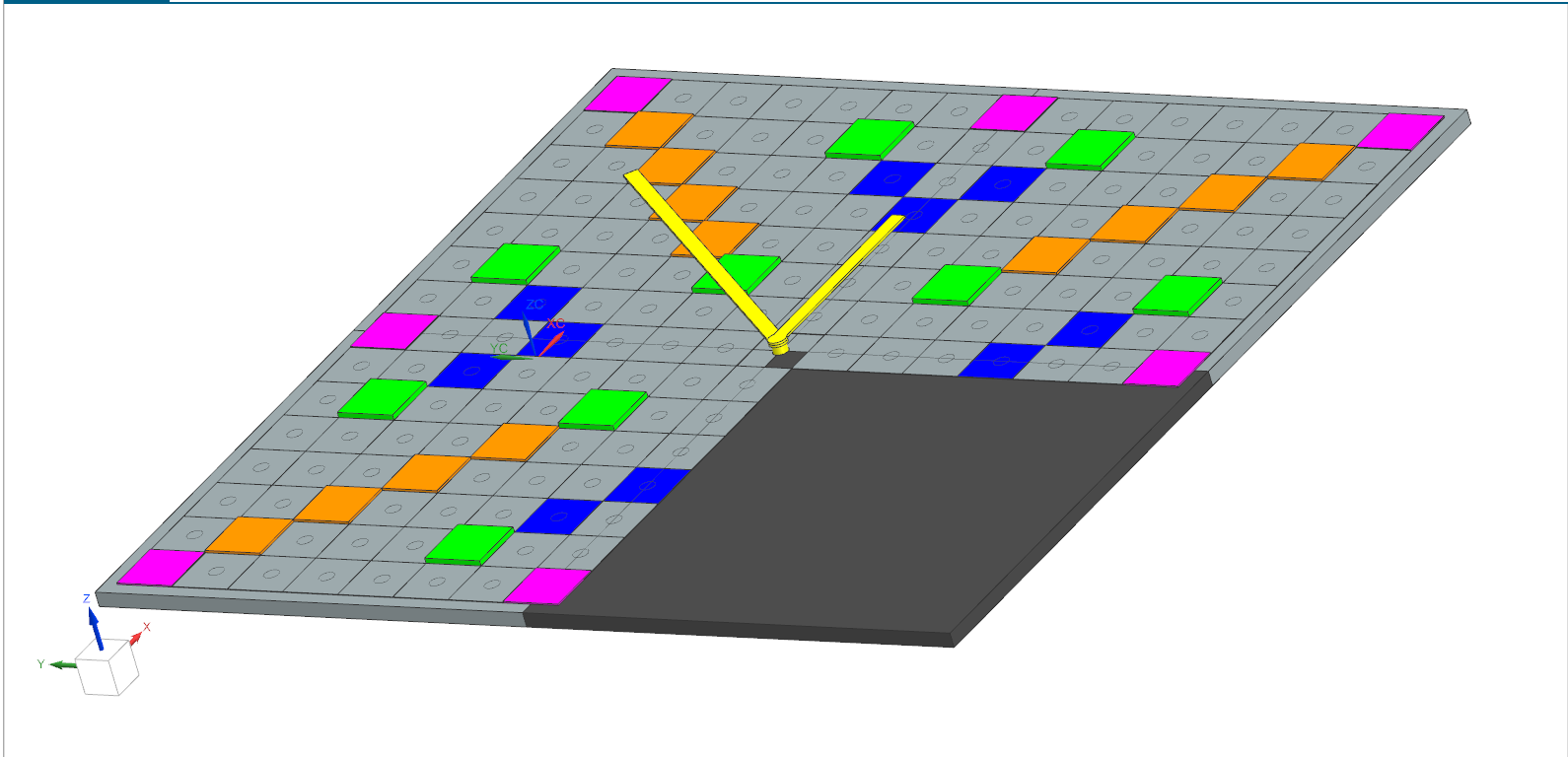

CAD Assembly (Using NX)

CAD Render (Using NX)

Staining wooden clock base

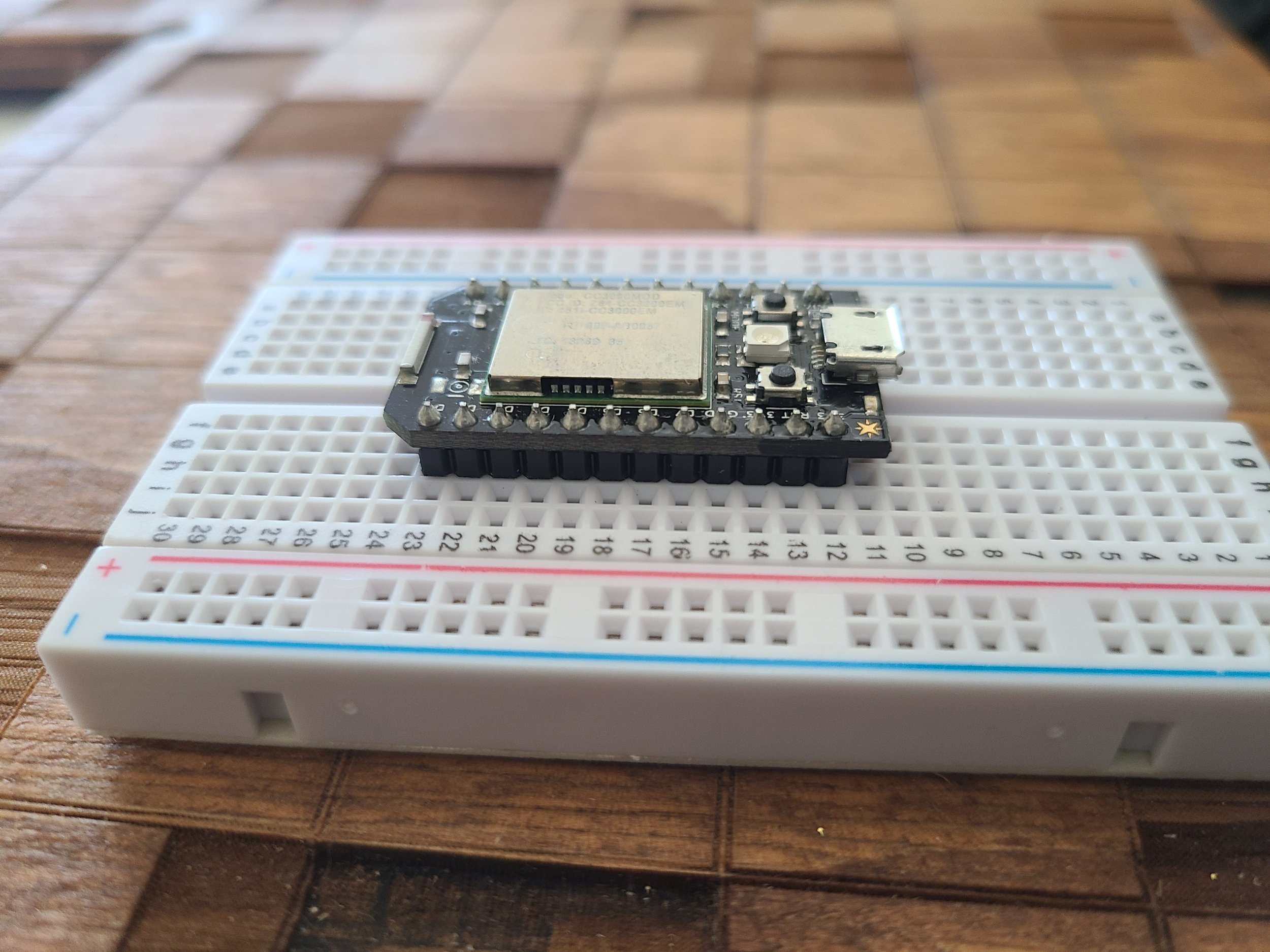

Spark Core and breadboard on clock base

Assembled clock!

Finished product at EDI design expo

Deliver

final product

Introducing Scrabbler, a product to help users learn all 1068 three-letter Scrabble words in a way that is effortless, quick, enjoyable, and comprehensive.

Project built on time in 2 week timespan

8 minute long presentation to a room of 50 people

Showcased skills in software and hardware (including Arduino IDE, a table saw, a laser cutter, hand tools, and soldering)

Demonstrated parts of my personality including desire to build using recycled materials and my quirky Scrabble side

how it went

Debrief

Hardware Reconsiderations

between Carvey mill rounded edges and laser cutter speed.

between sturdier bracing between front face and back plates was not sturdy

softer standoffs when wall mounting — buying them from McMaster or using a makeshift material (e.g. sponge)